Hotline Order:

(+91) 9920091165

Email ID:

sales@feplengg.co.in

You may be interested in…

Oil Mist Manifo...

FMC 750

Share:

₹15,000,000.00 Original price was: ₹15,000,000.00.₹11,000,000.00Current price is: ₹11,000,000.00.

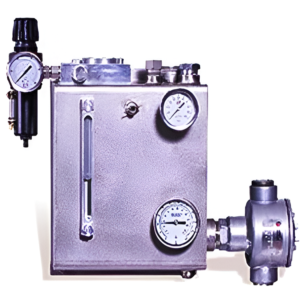

Oil Mist Lubrication Systems

An oil mist lubrication system is a centralized lubrication system that generates an atomized oil mist of greater than 3 microns, which is delivered directly to the equipment bearings. The system operates without any moving parts, using forced air to deliver a lean oil mist to each bearing house. A single system can provide lubrication for up to 80 pumps.

Proven Technology

Oil mist lubrication systems were developed in Europe in the 1930s for industrial use and were first utilized in refineries by Chevron and Exxon in the late 1960s. These systems can be incorporated into new projects or retrofitted into existing facilities. Applications include:

- Pumps

- Electric motors

- Gearboxes

- In some cases, turbines and pillow block bearings

Globally, there are over 4,200 large-scale systems (console type with less than 35 pumps) and countless smaller systems. Nearly 50% of refineries in India are currently using oil mist lubrication systems.

Benefits of Oil Mist Lubrication Systems

Superior Performance

Oil mist systems consistently deliver the precise amount of lubrication to the bearing, reducing wear, lowering operating temperatures, and eliminating particulates that can damage bearings.

Increased Reliability

The use of oil mist lubrication systems increases the reliability of rotating equipment, thereby enhancing the overall reliability of the plant. These systems are incredibly dependable, operating at very low pressures and without moving parts.

Cost Reduction

Over the past 40 years, oil mist systems have significantly reduced maintenance and operating costs. These savings not only recoup the system’s cost in a very short period but also increase uptime and overall plant productivity.

Safe Environment

Oil mist systems do not produce any hazardous vapor. Reduced maintenance requirements lower staff exposure to toxic substances. Additionally, these systems generate less waste, making them environmentally friendly.

Hotline Order:

(+91) 9892210905

Email ID:

sales@feplengg.co.in

You may be interested in…

Oil Mist Manifo...

Function/Description

- Main and Standby Mist Generators: Equipped with individual reservoirs of 33 liters each to ensure continuous operation.

- Oil Mist Density Sensor: Monitors and maintains the optimal density of the oil mist.

- Automatic/Remote Operated Air Pressure Regulator: Allows for precise control of air pressure.

- 300 Liter Bulk Tank: Stores a large volume of oil for prolonged use.

- Internal Bulk Tank: Prevents oil oxidation by receiving and storing the oil mist.

- Monitors and Controls: Ensures all mist generating variables are optimized.

- Air Temperature Control: Maintains precise control over mist density through regulated air temperature.

Material of Construction (MOC)

- Standard: SS 304

- Optional: SS 316/316L

1 review for FMC 750

Frequently bought together

FMC 750

Efficient and D...

Oil Mist Manifo...

Related products

FMC 1

Efficient and D...

FMC 10

Oil Mist Manifo...

Free Shipping

Home Decoration

Free Shipping apply to all orders over $100

Guaranteed Money Back in 30 days return.

10 Day Returns in case u change your mind.

- Electronics

- Furniture

- Medical Items

- Accessories

Get Free Shipping & 30% Off

Show all - Beauty

- Children

Get Free Shipping & 30% Off

Show all - Clothings

- Sport

- Sale

- TV & Monitor

- Cameras

sales –

Reliable and best quality!